Affordable indoor tracking system for manufacturers

An innovative and cost-effective indoor tracking solution designed for shop floors, offering real-time positioning resulting in high energy efficiency

Consortium

Six Partners, Five Countries, Boundless Possibilities

Gain greater insights into the project

Start Date

End Date

EIT Contribution

Total Cost

Countries

Partners

6

5

1.2 M

841 K

About The Project

TrackInWare aims at developing and commercializing a new indoor tracking solution

In the last decade, real-time tracking systems have been gaining relevance due to the advances of technologies and the increasing necessity in industry to use resources to their fullest potential. There are numerous technologies which can be deployed to track assets but no current technology offers at the same time accurate real-time positioning, at a competitive cost combined with a smart asset management software directly linked to the ERP software. This innovation project, co-funded by EIT-Manufacturing, started on 1st January 2023 and will be completed by 31st December 2024. It will upgrade the existing SIGSCAN solution (software, beacons and gateways) and commercialize the final kit: a low cost tracking system combining positioning accuracy, long working autonomy and beacons compatible with any kind of assets with the associated assets software management. The results will decrease production costs, increase manufacturing efficiency & enhance the assets management for all manufacturing companies regardless of their size and field of activity.

What We Offer

Cost Effective & Scalable Solution

To gain greater insights into their operations, manufacturers accelerated the adoption of IoT under the auspices of Industry 4.0. As an integral part of the IoT, the real-time tracking of assets is yet in great demand as a powerful tool for various use cases, as locating work equipment or goods, alerting for unauthorized movements, improving the production workflow, allocating the right resources or supporting the facility management.

Challenges

- Lack of accuracy of existing tracking systems

- High energy consumption of the beacons and gateways

- Weakness of the functionalities of the software

- High cost of the whole solution

It is compatible with various size of assets at low cost, alongside with the management software based on the data collected from the shopfloor.

TrackInWare offers a whole package of solutions at a reasonable cost to rapidly scale indoor tracking adoption by industrial companies.

Benefits

- Real-time and accurate positioning

- High energy efficiency

- Compatible with various size of assets

- Low cost

- Increase productivity

- Improve quality of operations

Technologies

For the indoor positioning system, we are currently using a combination of BLE (Bluetooth Low Energy) & Ultra-Wideband (UWB) Positioning.

Bluetooth Low Energy (BLE)

- Low energy consumption

- Compatible with most smartphones and tablets

Ultra-Wideband (UWB)

- High accuracy (centimeter-level)

- Ideal for real-time location systems (RTLS)

Main Features

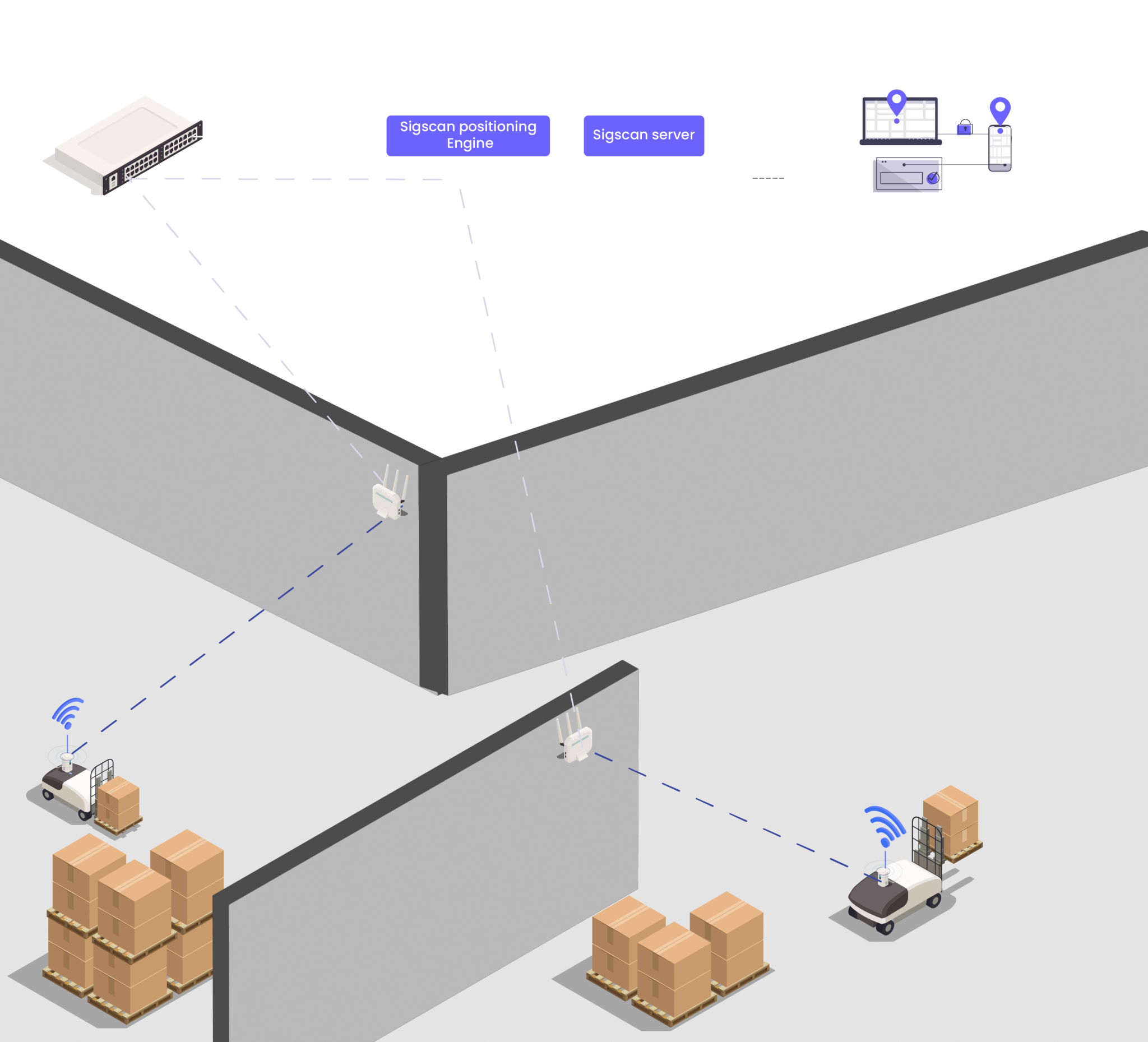

Components Involved in Indoor Tracking Systems

01

Beacon

Transmit signals to anchors for localization. Small, battery-powered, may support multiple technologies (BLE, UWB).

02

Gateway

Electronic devices that detect UWB pulses emitted by UWB Tags and forward them to the location server for calculating tag positions.

03

Positioning Engine

The positioning engine is a key part of indoor tracking systems, used to calculate and provide real-time location information.

04

Received Signal Strength Indicator (RSSI)

Estimates distance based on signal power attenuation.

Use Cases

Chemical Waste Management

BEKO Europe, formerly known as Whirlpool, aims to use the TrackInWare technology to track and monitor the process needed for the management of chemicals and chemicals waste in the frame of washing and cleaning process in the Cooking Factory in Italy. The TrackInWare technology will allow BEKO to track the movements of chemicals tanks from the moment in which they enter the factory until the disposal phase and delivery to the supplier.

Forklift Workflow Optimisation

Sonae Arauco is one of the main worldwide players of wood-based panels and aims to offer wood-derived solutions, with elevated quality, functionality and design. Sonae aims to improve their plant efficiency through the optimization of forklifts workflow and forklifts tasks allocation. With TrackInWare technology, SONAE will be able to track forklift movements in the warehouse and to recommend the best route for each task/group of tasks.

How it works

Learning Nuggets

Watch Demo Videos

TrackInWare Solution

Plant efficiency through affordable real-time tracking systems

TrackInWare is a European project funded by EIT Manufacturing. It aims at developing and commercializing a new indoor tracking solution, which provides a real-time and precise positioning with high energy efficiency.

SIGSCAN Logistics

SIGSCAN Logistics is a extended solution developed in the TrackInWare project. It’s designed to meet the indoor positioning needs in various industrial environments and focuses on accessibility and affordability.

Unlock the future of indoor tracking system

Tracking of any type of asset can be achieved through our solution